Temperature Control

WSIW Plastic Screw Chiller for Injection Molding

Adopting high-speed embedded microproces...

1:Embedded with microcontroller and high-resolution LCD touchscreen with a user-friendly interface.

2:RS485 communication protocol with PC monitoring and message control function.

3:The actual temperature can be checked at any time and its setting can be changed at any time.

4:The LCD displays parameters and the temperatures of outlet and inlet water.

5:The machine would display warnings, and can also save previous warnings for future references.

6:Installed with an imported compressor and highly efficient condenser, evaporator, and pipeline layout for effective cooling.

7:Multi-language interface is available.

8:The machine is completely protected from overloading, overheating, water shortage, and more.

Performance characteristics

Adopting high-speed embedded microprocessor controller and high-resolution LCD touch screen operation, the operation interface is simple and easy to understand.

Adopting RS485 communication transmission technology, the system reserves PC computer monitoring and SMS control functions.

You can check the actual temperature of each point at any time, as well as query the switch input and relay output, and modify the set temperature at any time. It can display temperature curves for one hour and one day.

The LCD simultaneously displays control parameters, outlet temperature, and return water temperature, making the working status clear at a glance.

Can query current and historical faults. With fault statistics function. Historical faults can be queried in three ways: fault number, fault frequency, and fault occurrence time.

The combination of a brand new imported compressor, high-efficiency shell and tube condenser, evaporator, and reasonable pipeline layout ensure high refrigeration efficiency.

Supports online switching of multiple languages.

Equipped with comprehensive safety and protection: delayed start, water flow fault detection, compressor frequent start prevention, outlet temperature compensation, power phase loss protection, reverse phase protection, overload protection, high and low pressure protection, outlet temperature low protection, water pressure low protection, heat dissipation insufficient protection, etc.

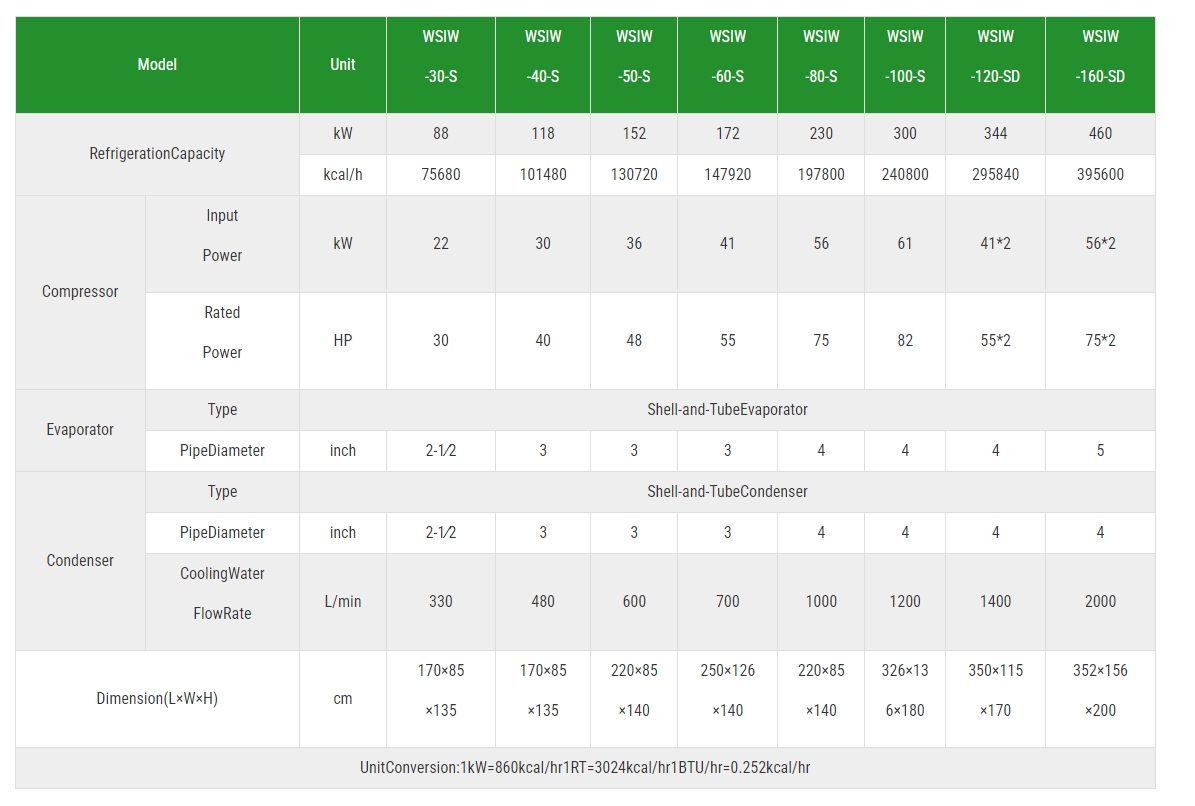

Technical Parameter

| Model | Unit | WSIW-30-S | WSIW -40-S | WSIW-50-S | WSIW -60-S | WSIW-80-S | WSIW-100-S | WSIW -120-SD | WSIW-160-SD | |

| Refrigeration capacity | kW | 88 | 118 | 152 | 172 | 230 | 280 | 344 | 460 | |

| kcal/h | 75680 | 101480 | 130720 | 147920 | 197800 | 240800 | 295840 | 395600 | ||

| Compressor | Input power | kW | 22 | 30 | 36 | 41 | 56 | 61 | 82 | 112 |

| Rated power | HP | 30 | 40 | 48 | 55 | 75 | 82 | 110 | 150 | |

| Evaporator | type | shell and-tube evaporator | ||||||||

| Water pipe diameter | inch | 2-1∕2 | 3 | 3 | 3 | 4 | 4 | 4 | 5 | |

| Condenser | type | Shell and tube condenser | ||||||||

| Water pipe diameter | inch | 2-1∕2 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | |

| Cooling water volume | L/min | 330 | 480 | 600 | 700 | 1000 | 1200 | 1400 | 2000 | |

| Overall dimensions (L×W×H) | cm | 170×85×135 | 170×85×135 | 220× 85×140 | 250×126×168 | 220×85×140 | 326×136×180 | 350×115×170 | 352×156×200 | |

| Unit Converter:1kW=860kcal/hr1RT=3024kcal/hr1BTU/hr=0.252kcal/hr | ||||||||||

Note: This table shows the condensation temperature at 35 ° C; The parameters under the working condition of evaporation temperature of 5 ° C.

Power supply: 3 Φ 380VAC 50Hz

The product specifications are subject to change without prior notice.

Temperature Control

Adopting high-speed embedded microproces...

Temperature Control

The application of a chiller in the cool...

Temperature Control

The application of a chiller in the cool...