The Differences Between Different Crusher Blades

2024-06-25 Page view:

Crusher machines feature different types of blades. Each blade design is designed to handle specific materials and achieve desired crushing results. For heavy-duty granulators by the Wensui V series, the series features two different models, VGY and VGD.

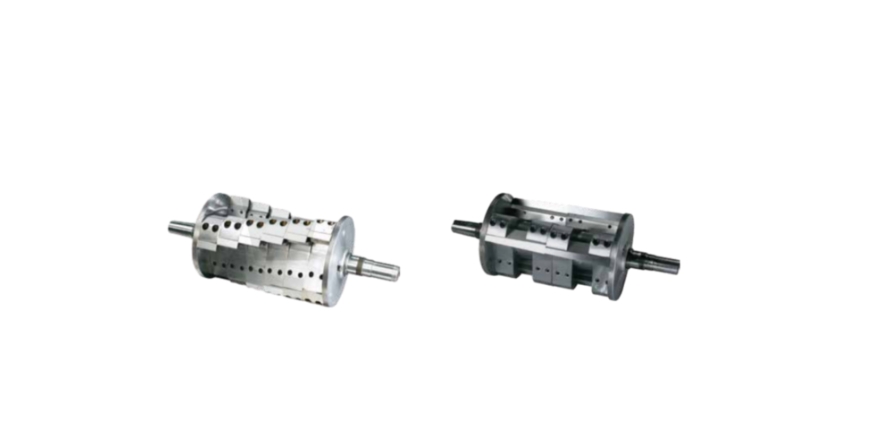

The blades of the V series crusher are divided into two types: claw blade and flat blade. Both blades offer high cutting performance, however, they are suitable for different applications. The following are the differences between the two blades:

1. Different shapes

Claw blade (left): staggered blades, composed of multiple blades to form a set of powerful blade bars.

Flat blade (right): the blade shape is flat and the cutting surface is wider than claw blades.

2. Different applications

Claw blade: plastic sheet, rod, lump, runner, molded part.

Flat blade: plastic film, soft rubber, filament, bottle (thin-walled hollow objects) and knitted bag.

3. Different functions

Claw blade: It uses the shearing effect generated by the rotating

claw blade during the cutting stroke to crush the material into the required particle size.

Flat blade: The rotor rotates to drive the blade to cut and crush the material.

Plastic Crushers

It is important to understand that each crusher model is equipped with a unique blade and rotor design. By choosing the appropriate blade type based on the material's characteristics, you can optimize the crushing process, improve operational efficiency, and extend the lifespan of your crusher machine.

With over three decades of manufacturing experience, we supply reliable and robust crushers and shredders for plastic waste recycling. The Wensui crushers are designed with special blades to ensure high cutting performance for specific application. Contact us to learn more.

-

2024-11

-

2024-10

-

2024-09

-

2024-09