The Benefits of Servo Robot

2024-09-09 Page view:

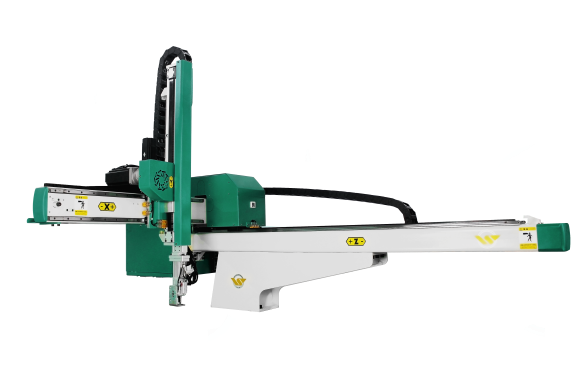

What is a servo robot? A servo robot is capable of mimicking the functions of human body parts for automatic control. This allows for automated equipment to perform operations according to preset requirements. The servo robot generally composed of hands, conveying tissues, drivers, manipulators and other bodies.

The working principle of a servo robot is driven by a servo motor. Due to the ability of servo motors calculating the detailed number of rotations, the distance of motion can be determined. The axis commonly used in servo robot is calculated based on the rotating parts, with one rotating part being considered as one axis. The control cabinet of the servo robot contains servo modules and computational substrates, which are used to control the actions of servo motors and calculate relative positions.

Due to the characteristics of flexible action, accurate positioning, and high load driving force, the servo robot is widely used in productions that involves automation such as chemical industry and logistics. The servo robot is greatly reducing the labor intensity and working conditions, improving production efficiency and operational safety.

Features

High-precision operation: The servo motor controls the robot to achieve accurate location control and positioning to ensure the consistency and accuracy throughout the production process.

High speed and efficiency: The action speed of servo robot is fast, completing more tasks in a shorter time and significantly improve production efficiency.

Flexibility and programmability: Servo robots have high flexibility and can be programmed according to different production needs, adapting to diverse production processes and product types.

Reduce labor costs: Automated robots can replace manual labor for repetitive or labor-intensive tasks, reducing reliance on human resources and lowering long-term labor costs.

Improve work safety: In some dangerous or harmful working environments, servo robots can replace artificial operations and reduce the occurrence of work injury accidents.

24-hour continuous work ability: Compared with artificially, servo robots do not need to rest especially in the industrial environment that requires continuous production.

Reduce production waste: Due to the consistency and repeatability of operations, servo robots can significantly reduce the scrap rate in the production process and improve product quality.

Easy to maintain and upgrade: Modern servo manipulators are typically designed with modular structures that are easy to maintain and upgrade.

Environmental adaptability: Servo robotic arms can work stably in various environments, including high/low temperature, humidity, dust and other harsh environments.

Easy to integrate: Servo robots can be easily integrated into existing production lines, working together with other automation equipment to form a complete automated production system.

In this era of automation, choosing servo robots is to choose a reliable production partner to lay a solid foundation for the long-term development of the enterprise.

Servo Robot Supplier

Start integrating robots to your production system. Share your requirements and operational concerns with us. We will deliver the right servo robot to you. With over thirty years of experience, we have a wide range of plastic processing equipment for your production.

-

2024-11

-

2024-10

-

2024-09

-

2024-09